INTEGRATION OF SOLVENT RECOVERY AND WASHING UNIT

Enviroxi 2.0 has all the solutions to integrate customer demand and adapts to their needs in order to be more efficient through recycling. Dirty solvents that come from printing machines and cleaning machine go through the solvent recovery process in order to be reused.

SOLVENT RECOVERY

The recovery unit is designed to distill dirty solvent from the self-cleaning presses or washers, in order to provide clean solvent to the presses and washers.

Distillation capacity is up to 80 l/h – 150l/h depending on the type of solvent to be treated and its characteristics: concentration, boiling point, superficial tension, the drying degree of the residue etc.

WASHING UNITS

The washing machine has been designed to obtain an automatic, fast and efficient cleaning of the utensils used in the printing machines, such a doctor blades, scrapers, ink

buckets, etc.

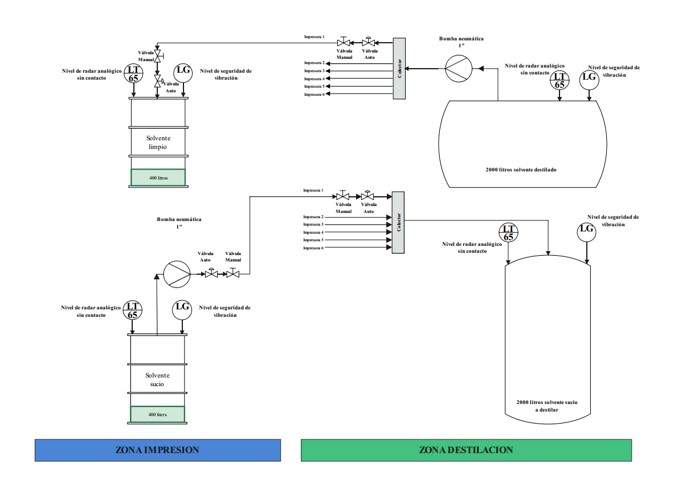

SOLVENT LOGISTICS

The solvent control system between the presses and the distiller is designed to obtain an automatic control of the clean and dirty solvent transport between the distillation zone and the printing zone. The system takes care of maintaining the desired levels in each tank and ,reducing the risk of overflows

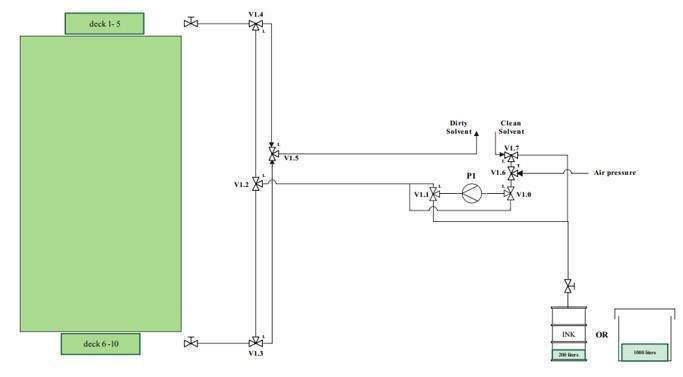

INK LOGISTICS

The ink control system is designed for the high consumption colors in the printer, so that the operator does not have to refill or control the levels of these inks. Through different levels, the system takes care of refilling the ink tank during printing. There is no need to stop the machine, as well as ink shortage errors.

SAVING ENERGY

The energy recovery system is designed to take advantage of the excess energy in the incineration systems, convert this excess into hot water or thermal oil and reuse it in order to reduce the consumption of gas or electricity.